Application Fields:

- milk and dairy products (also with pieces of fruit), ketchup, mayonnaise, mustard, sauces, dressings

- cleaning and washing agents, medical products (e.g. stomach gels), sterile injection products

- cosmetics

Working Principle:

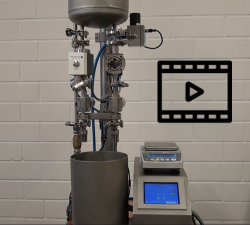

Electromagnetic flowmeters belong to the group of direct volumetric meters. They work according to the Faraday principle. They work according to the Faraday principle.In contrast to all other magnetic-inductive flow meters available in the market, they work in an alternating field instead of a synchronised DC field. This enables higher measuring dynamics and faster, precise measurements for dosing filling timing down to 100 ms. The batch controller regulates the flowmeters, valves and communicates with the PLC. Watch Video

Electromagnetic flowmeters belong to the group of direct volumetric meters. They work according to the Faraday principle. They work according to the Faraday principle.In contrast to all other magnetic-inductive flow meters available in the market, they work in an alternating field instead of a synchronised DC field. This enables higher measuring dynamics and faster, precise measurements for dosing filling timing down to 100 ms. The batch controller regulates the flowmeters, valves and communicates with the PLC. Watch Video

Special Features:

- shortest dosing times less than 100 ms possible

- small dimensions of the sensor

- conductivity >1µS/cm

- complete system for linear filling machines

- wide range of filling quantity with various diameters, easy adjustment

- direct control of the dosing valve

- easy CIP / SIP cleaning

- change of flow transmitter without re-programming possible

Compact Dosing Control:

The Compact Dosing Control Unit MDS-PLC configures the parameters and settings, visualizes the data and controls the valves.By using this compact controller, manufacturers can quickly integrate the dosing functions into their filling machines. No additional PLC is required. The compact controller is operated via the external inputs or via the touch screen.