Centec offer fully automated, skid-mounted process units and high precision measurement technology from a single source. This product range is nearly unique. Our systems and sensors are engineered to perfectly meet the most demanding requirements of the brewery, beverage, food and pharmaceutical industries. With a team of experienced engineers, we aim to create quantifiable added value for our customers by increasing the efficiency of their processes. We are your partner from planning and design through to commissioning of your plant. – whether it is a complete cold block for a brewery or a multiple-stage pharmaceutical water treatment regime according to cGMP and FDA guidelines.

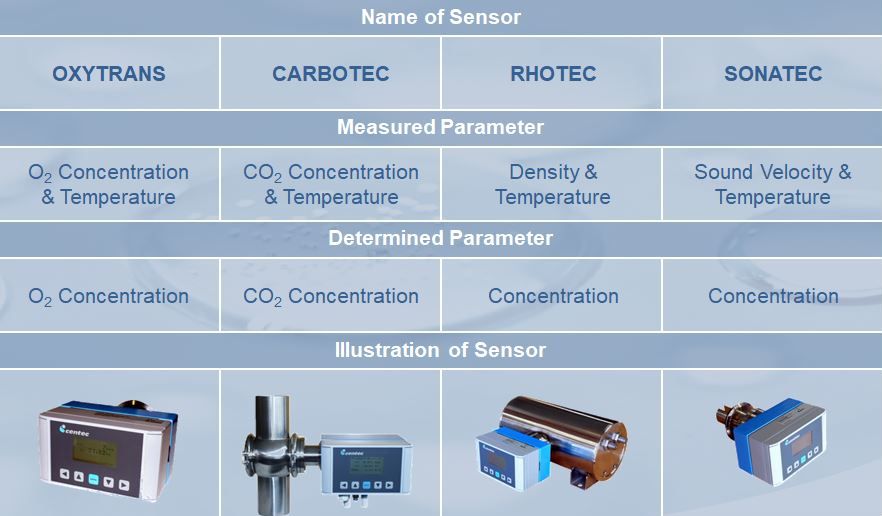

Sensors

Centec sensors are used in laboratory and process environments as stand-alone devices or as part of a process control system. Typical applications are measurement of:Centec sensors are used in laboratory and process environments as stand-alone devices or as part of a process control system. Typical applications are measurement of:

- Oxygen (O2) in liquids and gases

- Carbon dioxide (CO2) in liquids

- Density, sound velocity & concentration

(e. g. alcohol, °Brix, °Plato, vol. %, mass %)

Process Systems

Centec skids are customized to the greatest extend possible. They are used in beverage and food industries throughout the entire manufacturing process. We are a leading supplier of technologies for water purification and for water deaeration in most various fields.

- Water Pre-Treatment

- Water Softening & Disinfection

- Reverse Osmosis (RO)

- WFI Distillation

- Pure Steam Generation

- Water & Product Deaeration

- Wort Cooling & Wort Aeration

- Yeast Pitching & Yeast

Propagation

- Carbonation & Nitrogenation

- High Gravity Blending &

Carboblending - Multi Component Mixing

- Additive Dosing

- Pasteurization

- Dealcoholization

- Cleaning-in-Place (CIP)

- Valve Manifolds, Tanks &

Vessels