Industrial Temperature Devices

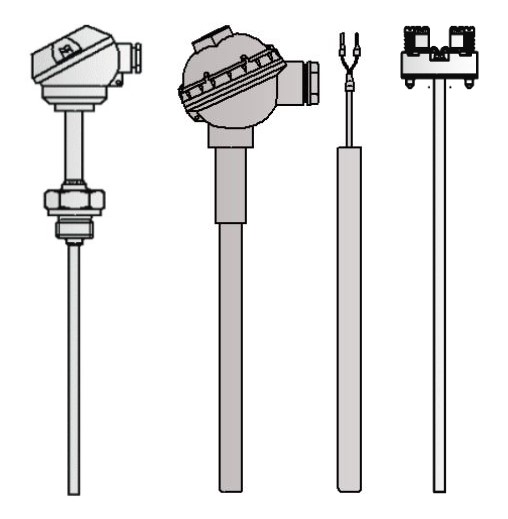

Industrial Temperature Measuring Devices describe probes with

- one (or more) temperature sensor elements (usually RTD or Thermocouple)

- a connection head (head sensors) or plugs, surface magnets/clips (cable sensors for machinery or surface measurement)

- a protection tube or Thermowell

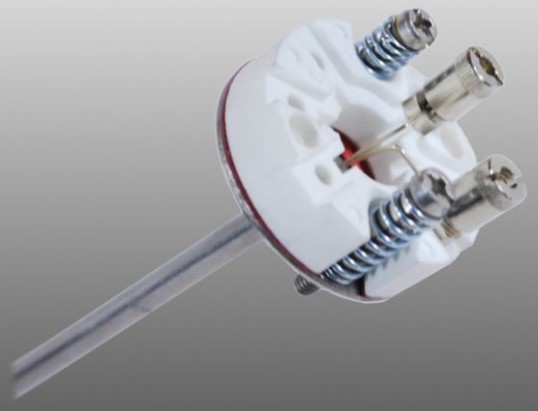

Sensor elements (inserts) are available as replaceable or non-replaceable types. They include the sensing wires, insulation materials and a shaft. Mineral insulated inserts are bendable and protect against vibrations, ceramic types are used for high temperatures.

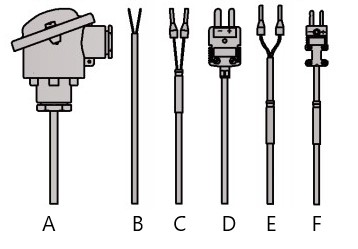

Head sensors include the sensing elements which is connected to connection heads or head mounting transmitters (A). They can be fitted to the pipe or to extension tubes (Thermowells) by flange, threaded or with a clamp on (for hygienic aplications).

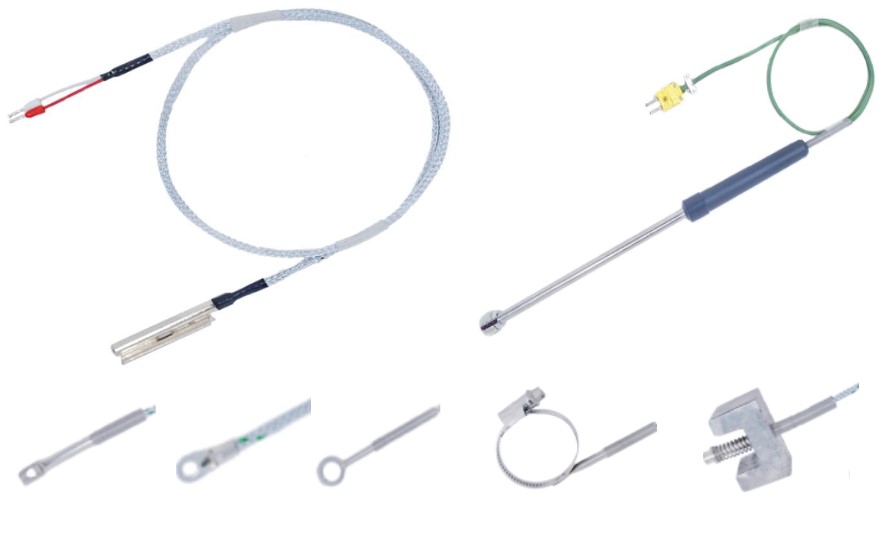

Cable sensors are used for

- movable or replaceable parts of machines and devices, (compressor, turbine,...)

- outer surface measurement of devices and machines, especially their bodies, blocks

The inserts are connected to a head (A), exposed wire ends (B), with sleeves (C), plugs (D) and/or compensation cables (E, F).

RTD Sensor

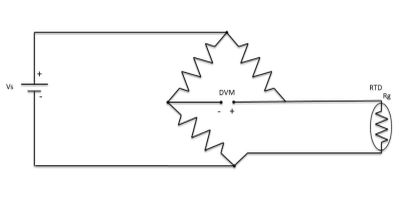

An RTD is a temperature sensor to measure temperature using the principle that the resistance of a metal changes with increasing or decreasing temperature. They required an electrical current (exitation current) which is transmitted through a piece of metal, called the RTD element or resistor. RTDs have a near linear response to temperature changes, they are stable and accurate and give repeatable responses.

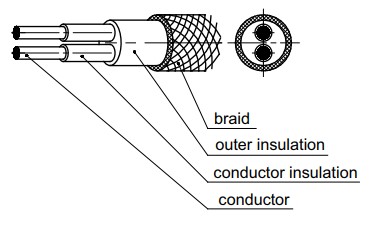

Most RTD elements consist of a length of fine coiled wire (most commonly Platinum, Nickel or Copper)

wrapped around a ceramic or glass core. The element is usually quite fragile, so it is often placed inside a sheathed probe to protect it.

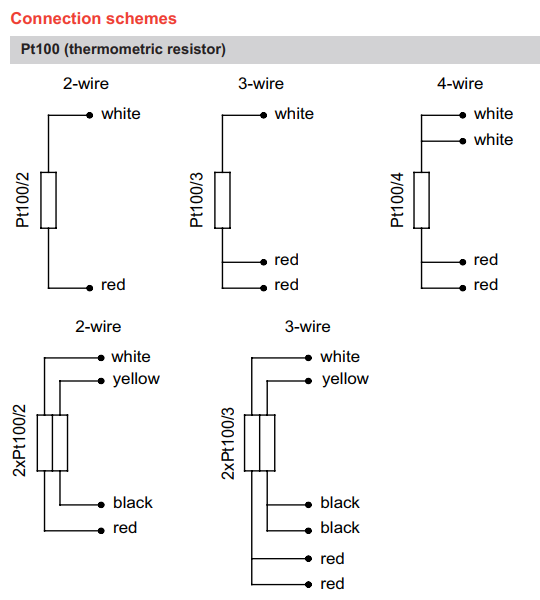

RTDs are available in 2, 3 and 4 wire configuration. (2 wire for short lead length, 3 wire (most commonly used) adds a line for the exication current to cancel the wire resistance effect, 4 wire config for highest accuracy)

The PT100 probe (el. resistance of 100.00 Ohm at 0°C) is most commonly used in industrial applications. PT500 (500 Ohm at 0°C) and PT1000 (1000 Ohm at 0°C) probes are available.

| Advantages | Limitations | |

|

|

Thermocouple Sensor

Thermocouples are the most commonly used temperature sensors. Thermocouples are self-powered, (require no excitation current), can operate over a wide and high temperature range, and have fast response times.

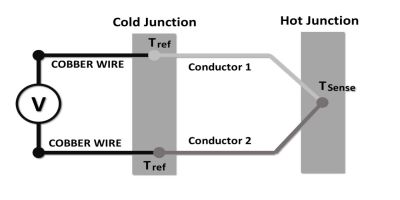

Two dissimilar metal wires are joined together forming an electrical junction. The temperature difference of the two dissimilar conductors produces a temperature dependent voltage as a result of the thermo electric effect, (Seebeck effect). The voltage is measured and used to calculate the temperature.

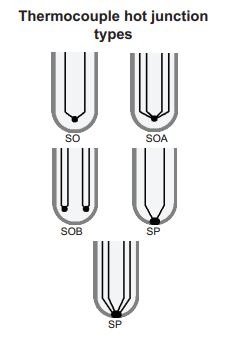

There are different hot junction types: insulated hot junction (SO), grounded hot junction (SP), one hot Junction for 2 TC insulated from the sheath (SOA), hot junctions insulated from each other and from the sheath (SOB).

Thermocouples have a built in electronic cold junction compensation to correct the missing thermoelectric voltage due to the fact that the thermocouple cold end at the instrument is not at 0°C.

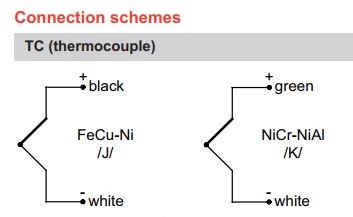

There are several types of thermocouples made from different materials for different temperature ranges and different sensitivities. The most commonly used is the K type. Here a list of the common types of thermocouples:

| Type | Range | Application |

| Type K (Nickel-Chromium / Nickel-Alumel) | –270 to 1260 °C | most common, nuclear application |

| Type J (iron–constantan) | −40 to +750 °C | oxydizing atmospheres |

| Type T Thermocouple (Copper/Constantan) | −200 to 350 °C | cryogenics, ultra low freezer |

| Type N Thermocouple (Nicrosil / Nisil) | −270 to +1300 °C | comp. type K, better oxydation at high temp |

| Type E Thermocouple (Nickel-Chromium/Constantan) | −110 to +140 °C | strong signal, high accuracy |

| Type B Thermocouple (Platinum Rhodium – 30% / Platinum Rhodium – 6%) | 0 to 1700 °C | high accuracy and stability for very high temperatures |

| Type R Thermocouple (Platinum Rhodium -13% / Platinum) | -50 to 1480 °C | very high temperatures |

| Type S Thermocouple (Platinum Rhodium - 10% / Platinum) | up to 1600 °C | high temperatures, Pharma and Biotec Applications |

Compensation and extension cables are the element of measuring installation connecting thermocouple sensor with measuring device e.g. controller, indicator or temperature recorder. Extension cables are made of the same materials as thermocouples, whereas compensation cables are made of substitute materials with properties similar to thermocouples. Cable insulation are selected according to ambient conditions and operating temperature.

Accuracy classes: Class1 0.4%, Class 2 0.75%

| Advantages | Limitations | |

|

|

RTD vs Thermocouple Sensor

|

Parameter |

RTD |

Thermocouple |

|

Technology |

Fine coiled platinum wired around ceramic core |

2 disimilar metals welded at one end, self powered |

|

Measurement unit |

Ohm (Resistance) |

Volt (Voltage) |

|

Typical Range |

-240 to +650°C |

-270 to 2320°C |

|

Long term stability, drift |

Excellent |

Poor to fair |

|

Accuracy, Repeatability |

Excellent |

Medium to good |

|

Response time |

Good |

Medium to excellent |

|

Linearity |

Good |

Fair |

|

Undesirable self-heating |

Medium to excellent |

Excellent |

|

Wire extention |

Copper wire, shielded, grounded |

Compensation or extention wires required |

|

Stability |

Fragile |

Stable against vibrations |

RTD Working Principle

Thermocouple Working Principle