Application

Pharmaceutical products are sterilely filled in special machines and plants. The hereby used containers (usually glas containers – vials), have to be cleaned and sterilised.

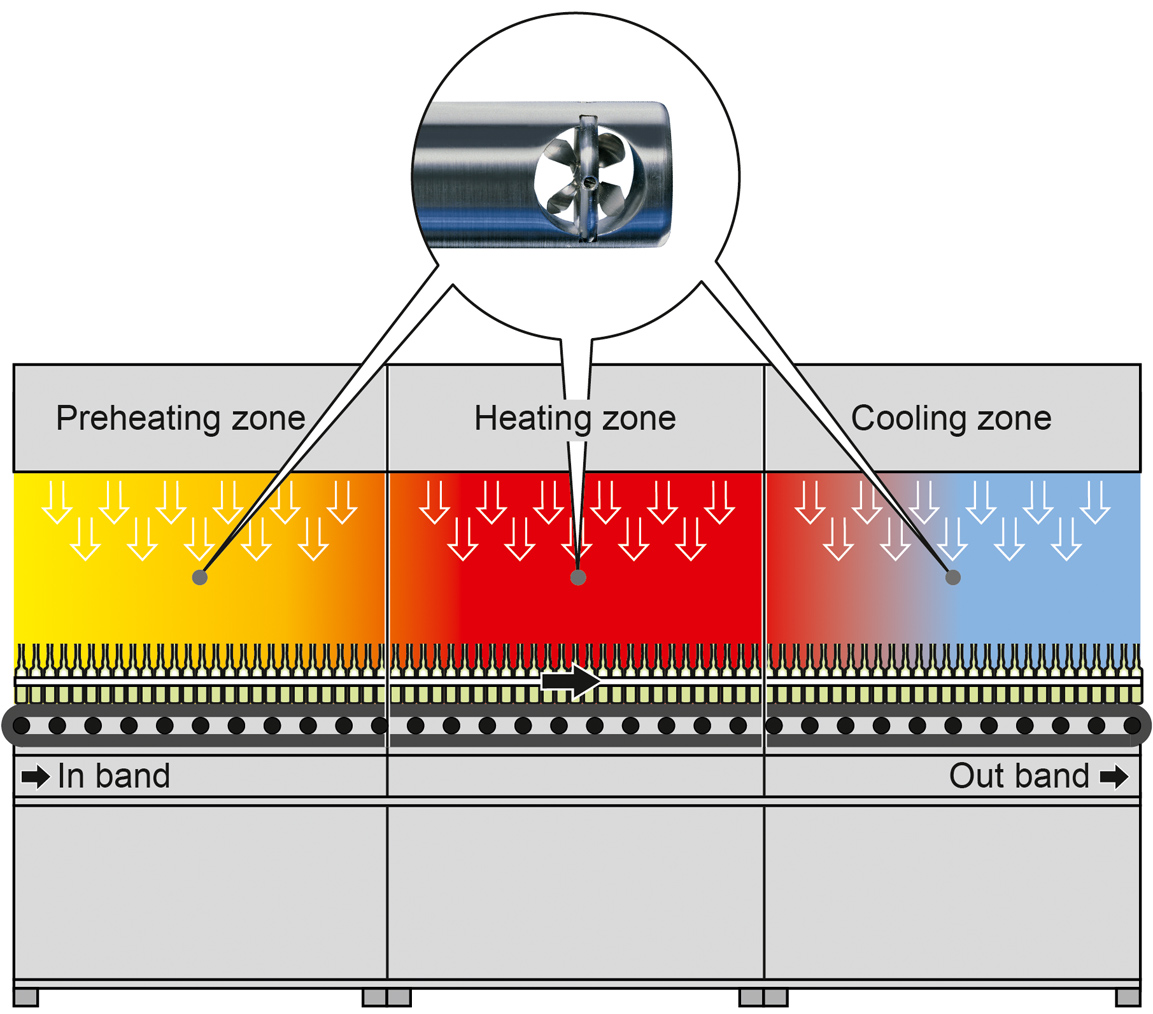

After washing, the vials are led to a sterilizing tunnel for sterilisation. They are transported with a special conveyance through a preheating zone to the heating zone of the hot air steriliser. Hot air is blown onto the vials to sterilise and depyrogenate them.

In sterilizing tunnels hot air flows through the so called HEPA-filter down into the heating zone. There, sterilizing hot air with a very low flow velocity is blown down to the glas containers.

Since it determines the process, flow velocity needs to be measured and monitored closely.

Process data

Measuring task:

Flow velocity for process regulation

Measuring point:

At different points of the sterilising tunnel, also in the heating zone

Measuring range:

Up to 1 m/s

Process pressure:

Atmospheric

Process environment:

Up to 300 °C

Advantages:

Safe

The process is continuously regulated and ensured by flow velocity measurement

Robust

Our sensors are perfectly suited for use in the heating zone in temepratures higher than 300 °C

Tried and tested

Well-known plant manufacturers have been valuing our sensors for decades.