Gas Measuring Technology for flow rate, mass flow rate and flow velocity

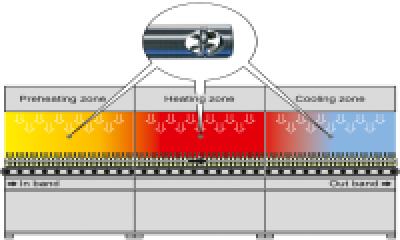

Hoentzsch flow sensors and flow rate measuring instruments demonstrate their strengths and outstanding excellence even for applications requiring extreme specifications and measurement requirements. Some examples are: explosive atmospheres, aggressive mediums, gases with temperatures up to 550 °C, mediums with particle or condensate content, high flow velocities up to 200 m/s, pipe flows with changing gas compositions or flow direction, and many more. The main focus of the flow rate measuring instruments here in use is measurement of gas flow rate. Höntzsch also offers a wide spectrum of flow rate measuring instruments and flow sensors for measuring the flow rate of liquids.

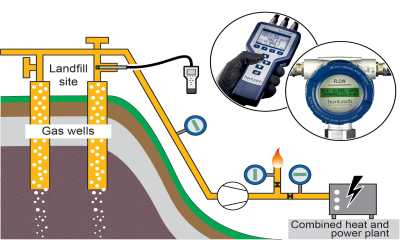

Our application-specific, high precision instruments for measuring the flow velocity and flow rate of gases can be used in many industrial sectors such as chemical, pharmaceutical, automotive, and semiconductor industries as well as in power stations, waste water and biogas plants, waste disposal, landfill sites, to name just a few. Here some examples:

Gas Flow Products

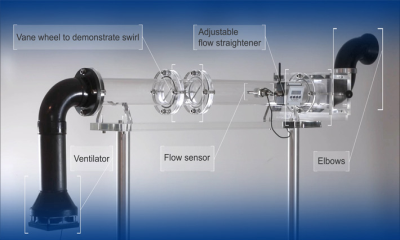

Vane Wheel FA Flowsensor

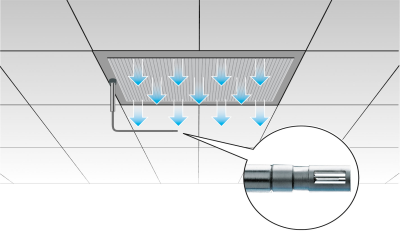

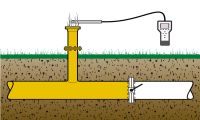

Flow rate and flow velocity in pipes and ducts, measuring flow profiles, aerodynamic research, measuring laminar flow, also at high gas temperatures, landfill gas, exhaust gas, flow rate and flow velocity in flowing waters.

Vortex VA Flowsensor

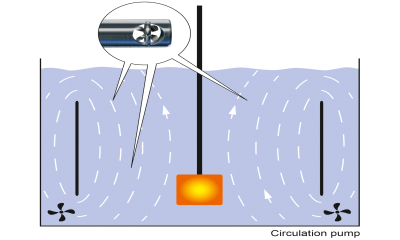

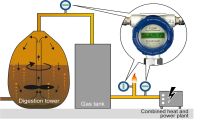

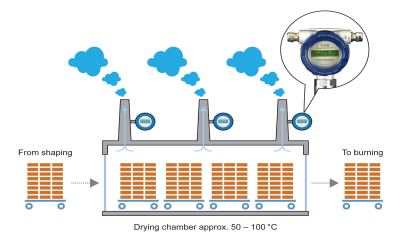

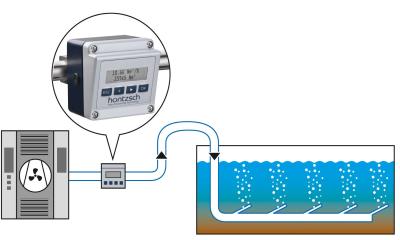

Flow rate and flow velocity measurement in wet and/or particulate-laden gases, biogas or exhaust gas, also according to Clean Air Guidelines, (TA Luft). Flow rate measurement of sludge aeration air, sewage gas, landfill gas, water vapour and engine intake air on test stations. Flow velocity in climatic wind tunnels, diluted car exhaust gas, traffic tunnels and in nuclear reactor technology.

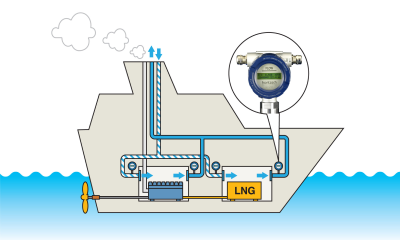

Thermal TA Flowsensor

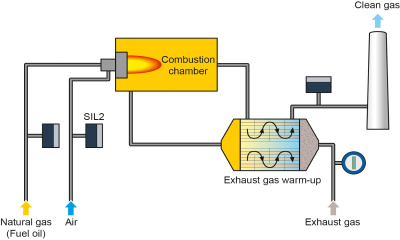

Fixed and portable consumption measurement in compressed air, nitrogen, natural gas, methane, helium, argon, carbon dioxide, hydrogen, SF6; measuring laminar flow, burner supply air, leakage flows; monitoring safety-related installations, also in aeronautical applications.

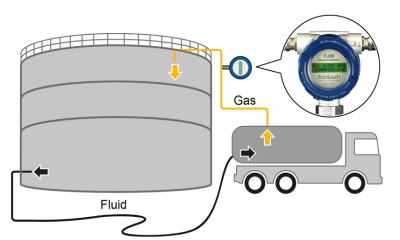

Ultrasonic UA Flowsensor Exactsonic II

This principle of measurement is also referred to as the transit time difference method. For measuring the flow rate of liquids using this technique, ultrasonic pulses are sent and received simultaneously through the medium in the direction of flow and against it. The sensors work alternately as transmitter and receiver. The transit time of the acoustic signals filtered through the medium in the direction of flow is shorter than that against it. The difference in transit time Δt is measured and can be used to calculate the average flow velocity of liquids filtering through the acoustic path. After measuring the flow velocity and with the pipe cross-sectional area, volumetric flow can be calculated.

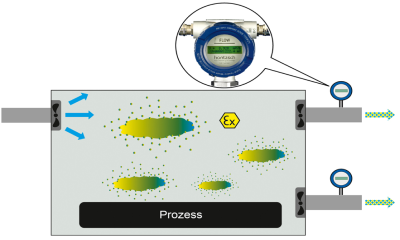

Handheld flowtherm Ex

In combination with flow sensors FA, VA, TA, Pt100 and others for applications in hazardous areas

Measuring applications with the flowtherm Ex are manifold: gas mass flow and flow rate in air, exhaust air, process gases, particle and condensate laden emissions, vehicle exhaust emissions, in aggressive gases with high working temperatures and, most importantly, in the hazardous area Zone 1, et al.

ATEX-approved for potentially explosive atmospheres: II 2G Ex ib IIC T4