Advantages:

- Low Pressure: 'The large diaphragm size allows a measuring range starting from 16 mbar (vs 600 mbar of Bourdon tube PG).

- Overload Protection: As the diaphragm is supported by the upper flange, the gauge offers a much higher overload safety, (up to 40 bar).

- Aggressive Environment Protection: Membranes with specialized materials (e.g. Tantallum) or protective coatings, (e.g. PTFE or XYLAN) and linings as well as protective materials for the socket or lower flange make it suitable for applications with corrosive media and atmospheres

- High Viscosity Media:the open measuring flange allow the use of viscous, crystallizing media with solidifying particles

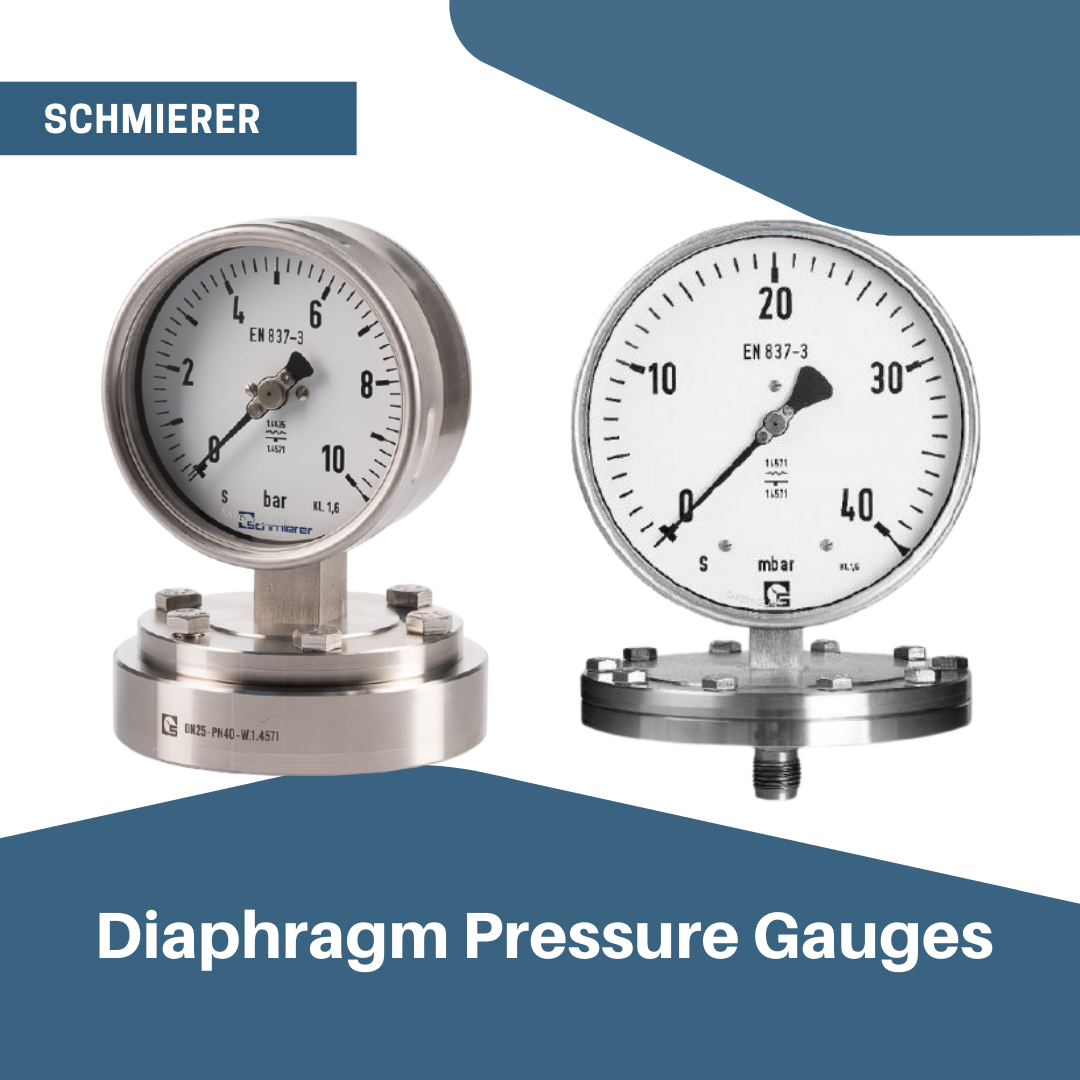

In Diaphragm Pressure Gauges a thin corrugated membrane is built-in between two flanges. The applied pressure is deflected on the diaphragm and carried over via a gear segment to the movement with the attached pointer.

Pressure Range:

- PGU series: 0-16 to 0-400 mbar - overload safety up to 10 bar

- PKU series: 0-1 to 0-25 bar, -1 -0 to -1 to 25 bar - overload safety up to 40 bar

For aggressive media we recommend the Graphene infused Xylan 1427 membrane coatings, (waterborne/VOC-compliant, resin-bonded, thermally cured, single-film, dry-film lubricants) with pressure ranges from 0-6 to 0-25 bar. Highly aggressive media require Tantallum foils or PTFE/ECTFE coating. The Manodamp® Pointer Dampening Movement stabilizes the gauge against vibrations.