Variable area flow meters with borosilicate glass cones from Kirchner Germany, are cost-effective and reliable instruments used for water, air or transparent fluids in processing plants in the F&B, Chemical, Petro-Chemical, Furnace, Water/Waste Water and other industries.

The borosilicate glass measuring cone is customized with media specific scale and located inside a perspex half shell shatter proof protection tube. They are installed in pipelines by means of pipe unions or mounted between flanges. Explosion proof models are available. In addition to the visible flow detection the VA flowmeter can be installed with electrical limit value switches or linear position sensors (4-20mA) which are adjustable throughout the entire measuring range for flow monitoring. The SGM series covers chemical applications with high pressure, temperature for acidic process media.

Working Principle

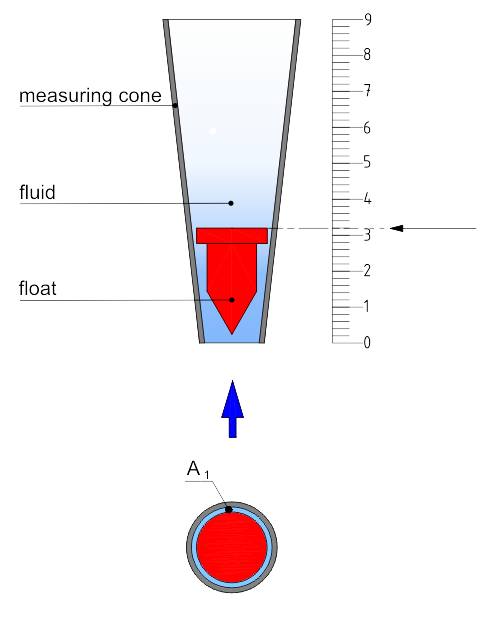

The float can easily move up and down in the conical measuring tube.

The float can easily move up and down in the conical measuring tube.

The vertical position of the float, obtained as a function of the flow velocity of the measuring media, is an indication of the flow rate.

This flow rate can be read directly on the scale of the measuring tube.

With increasing volume flow, the annular gap surface area A around the collar of the float increases (A2 > A1).

Mounted between flanged or pipe unions (treaded)

Mounted between flanged or pipe unions (treaded)