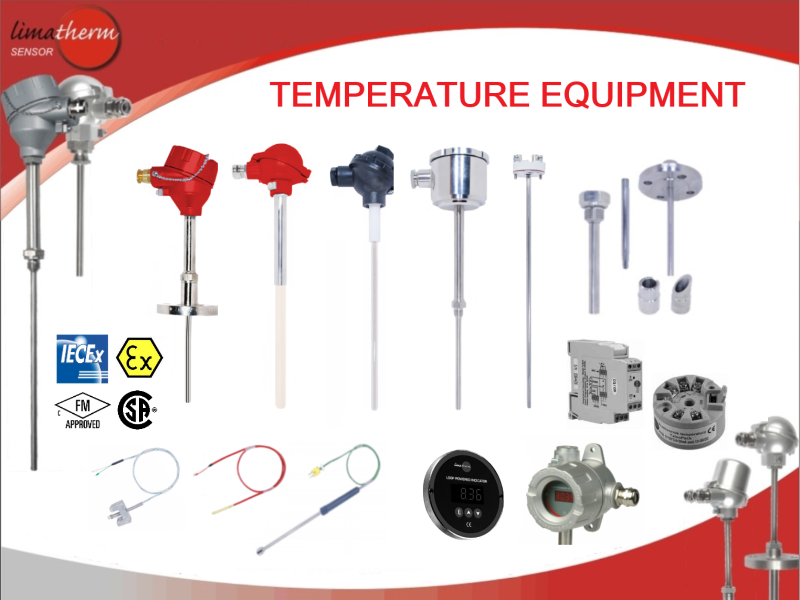

Temperature sensors (TC, RTD) - certified flameproof and intrinsically safe solutions for hazardous areas - wireless solutions

"Limatherm Sensor" is an European manufacturer of all types of temperature sensors:

- head sensors, inserts, cable sensor for machinery and surface, thermo-electric

- customized solutions: flameproof - intrinsically safe, mineral insulated, wireless

- special applications: chemical, aggr., HVAC, high temp., power stations, high purity F&B, Pharma, Ships

- accessories: sensor heads, thermowell, transmitter, inserts, cables, glands

- complete Ex proof units (housing & sensor)

- certified (ATEX, IECEX, CSA, FM)

- accredited (TÜV Nord, ILAC MRA, PCA)

- one place factory - short delivery times - cost efficient

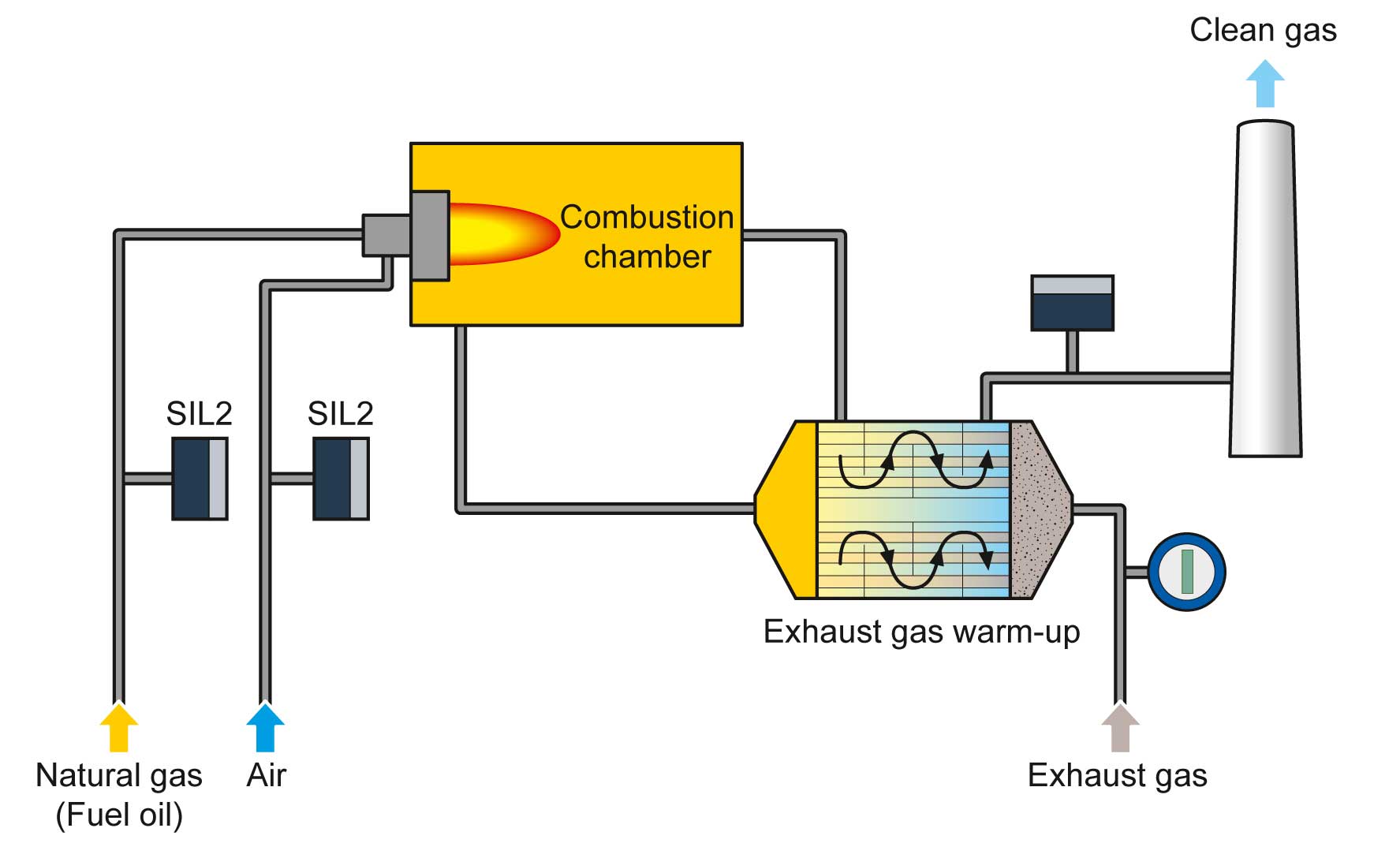

Thermal or thermal regenerative post-combustion is the process of cleaning industrial exhaust gases. Contaminated air, explosive process gases, flare and waste gases are lead to a combustion chamber and burned in temperatures between 700 °C and 1,200°C.The Höntzsch Vortex sensor with ATEX and SIL certification measure the flow rate of inflowing, solvent-containing exhaust air to manage the high energy consumption in combustion. They are robust (no moving parts) with longevity and minimal maintenance.

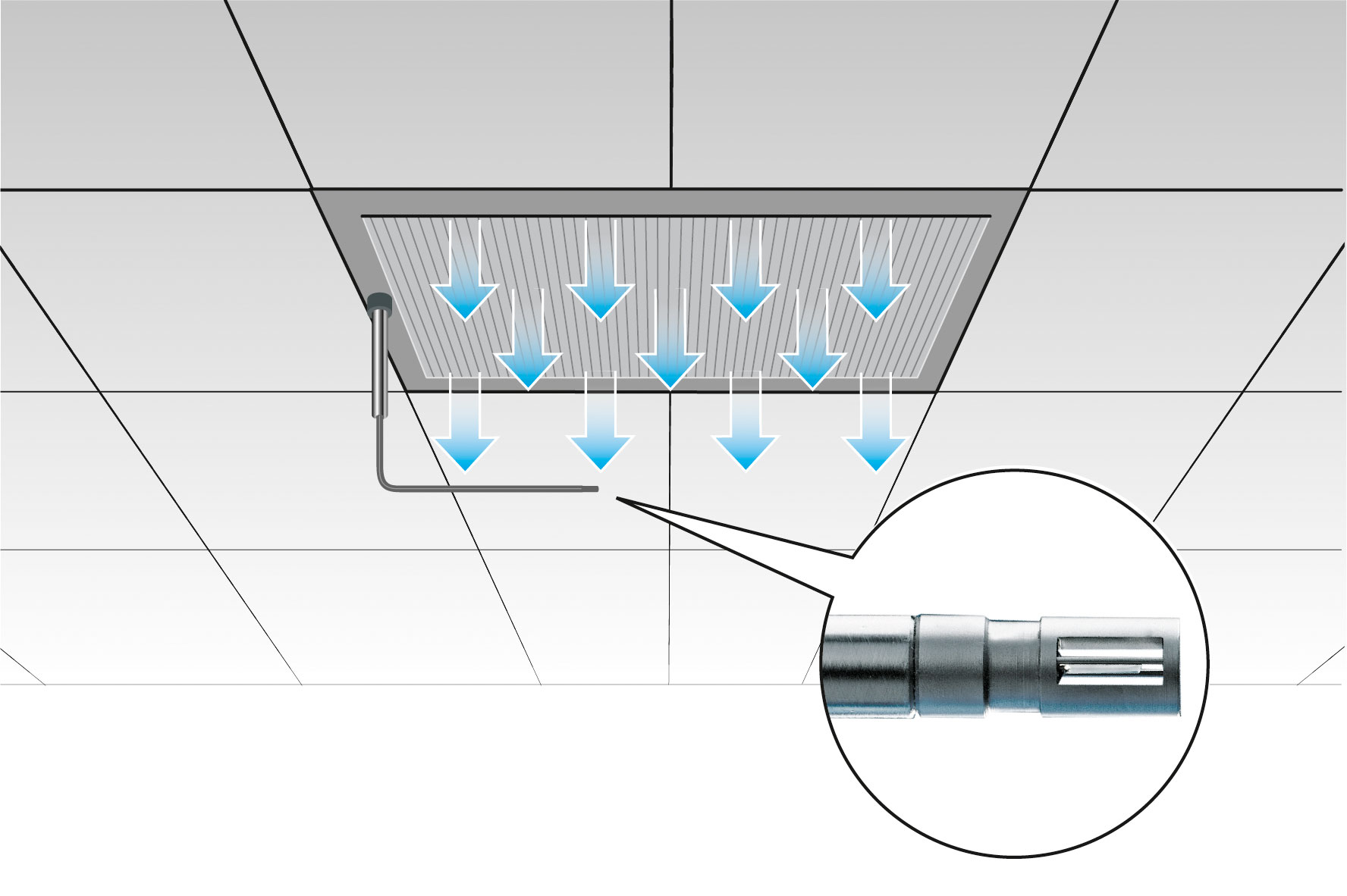

In sterilizing tunnels hot air flows through the so called HEPA-filter down into the heating zone. There, sterilizing hot air with a very low flow velocity is blown down to the glas containers and monitored with Hoentzsch Vane Wheel Flowsensors.

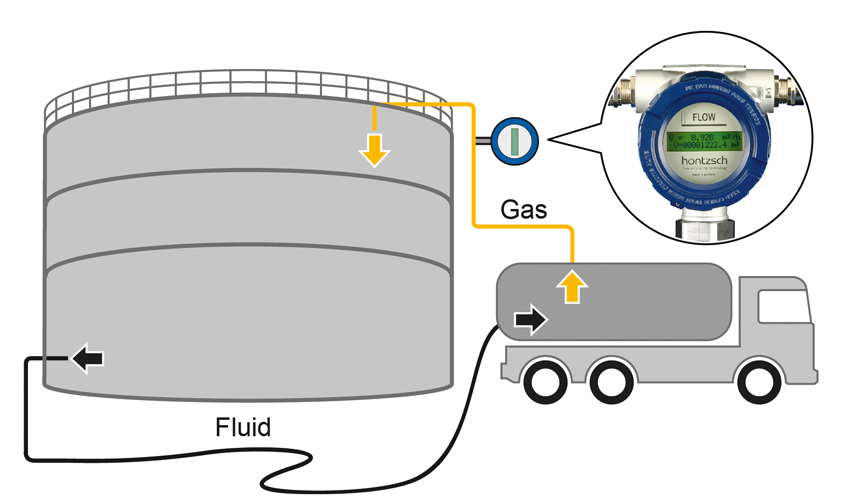

Measuring flow rate in the recovery gas pipe during gas recovery

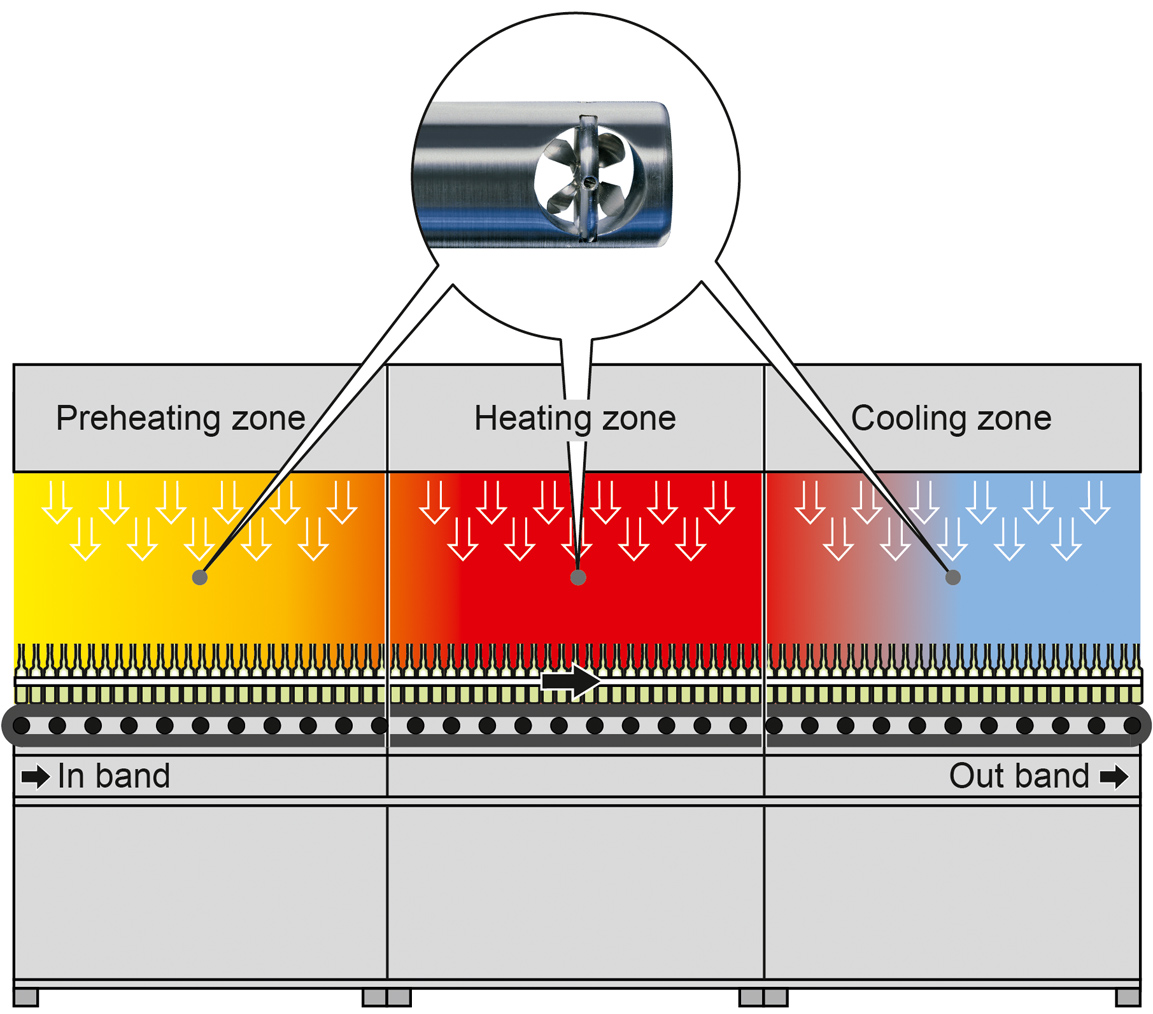

Flow velocity for process regulation for paint booth, clean rooms, semiconductor and filling and packaging applications.